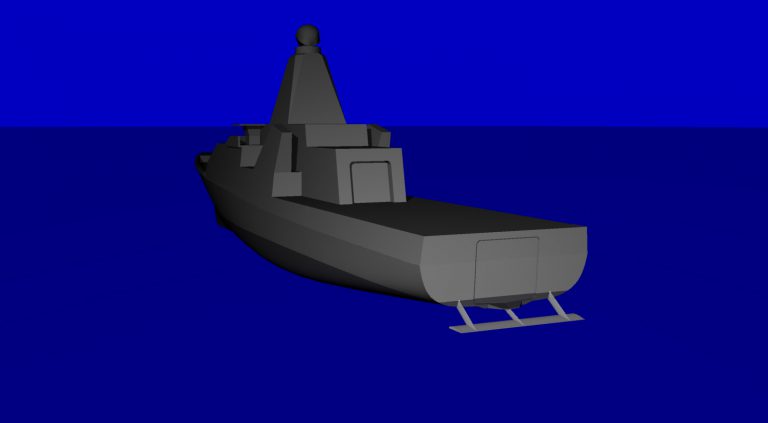

The Hull Vane® saves 12.5% on Holland Class OPVs

This was the question asked by the DMO (Defence Materiel Organisation) of the Royal Netherlands Navy. A CFD study was done to find the answer. Based on the operational speed profile and the power curve of the ship, it was determined that the most fuel is consumed per year at speeds between 15 and 20 knots, in spite of the fact that the ship sails 86% of the time at speeds below 15 knots.

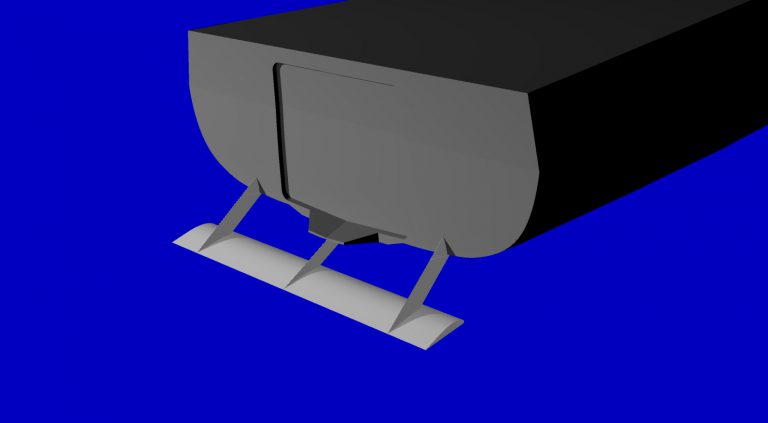

The Hull Vane® was therefore optimized for a speed of 17.5 knots. As the vessel has a pronounced trim wedge – incompatible with a Hull Vane®– the trim wedge was partially modified to the limits set by the DMO. Subsequently, CFD runs were done to determine the resistance at 5 knots, 12.5 knots, 17.5 knots and 22.5 knots, showing resistance reductions of 1.3%, 13.7%, 15.3% and 11.1% respectively. Multiplied by the operational speed profile, this results in an annual saving on fuel and emissions of 12.5%. The amount of CO2 emissions avoided will exceed 1.000 tons per ship per year, making the Hull Vane® an extremely cost-effective CO2 abatement measure, as the investment will be paid back many times over during the lifetime of the ship.

For the influence on the operability of the vessel, a seakeeping analysis was done in a typical wave condition. This showed a reduction of the pitching movements of 7% and a reduction of the vertical accelerations on the helicopter deck of 13%. As the vertical accelerations are the limiting factor for heli-operations, this will enlarge the operational envelope of the vessel.